1. Industry profile

Rock wool is an inorganic material, which is made of basalt as the main raw material. After melting at high temperature, it is drawn into fiber by centrifugal force of high-speed centrifuge. At the same time, a certain amount of binder is sprayed into it. After curing and cutting, a series of technological processes are carried out. It has excellent performance of heat preservation, sound absorption, heat insulation, fire prevention and air permeability, and it is a new type of building material. Rock wool products are internationally recognized as the main energy-saving materials in the “fifth conventional energy”. Every time 1 m2 of rock wool products are used for thermal insulation, the average energy saving is 10 000 kg / h, which is equivalent to saving 3 T standard coal every year. For every 1t of rock mineral wool products used for thermal insulation in buildings, energy equivalent to 1 t of oil can be saved in one year.

Rock wool products can be divided into plate, felt, belt, seam felt, pipe, strip and other products. According to the characteristics of the products, they can be widely used in petroleum, chemical, electric power, metallurgy, construction, transportation, agriculture and other fields.

2. Development status of rock wool abroad

There are four major rock wool producers in the world: rock wool of Denmark, paroc of Finland, Knauf of Germany and Saint Gobain of France, with the production capacity of 180, 35, 32 and 32 million tons respectively, and the maximum production capacity of a single line is 50-100 thousand tons. The product quality is excellent, representing the highest production technology level in the world.

From the perspective of rock wool production technology and equipment, rock wool manufacturing companies in various countries have their own characteristics and differences in key technologies such as melting, fiber forming, cotton gathering, pendulum, pleating, curing and cutting. While considering how to improve the production capacity and quality of products, each company also considers how to improve the diversity of products, expand the application fields of products, how to reduce production consumption, reduce the operation and maintenance costs of production lines, and how to be more environmentally friendly.

In terms of production capacity, the annual output of rock wool products abroad has exceeded 7 million tons, mainly concentrated in developed countries, and the annual production capacity of EU alone has reached more than 4 million tons. In terms of application: most of European rock wool products are used for building thermal insulation, building sound absorption, building fire prevention, etc. in the UK, rock wool construction consumption accounts for 85% of the production capacity. Rock wool as a cost-effective building thermal insulation and fire-proof materials, Europe began to promote the use of the 1960s. In addition, the rise of rock wool as a kind of soilless cultivation technology as plant growth matrix has made the application of agricultural rock wool develop rapidly in Europe and America. In this regard, the Netherlands and the United States have done better.

3. Development status of rock wool in China

China’s rock wool manufacturing industry started relatively late, and its domestic popularization rate was less than 10 years. In the early years, it was mainly to produce low-end mineral wool. In the late 1950s, China began to introduce mineral wool production technology, and it was not until the end of 1970s that the industry began to form. The 1980s can be said to be a great leap forward in the history of China’s mineral wool industry. Both the production scale and the production technology have made great progress. The main reason is that China has introduced more than 10 mineral wool production lines of different styles and scales from six countries, thus laying the foundation for the development of rock wool in China.

With the improvement of people’s awareness of building energy conservation in recent years, the excellent characteristics of rock wool have been gradually accepted. Especially after the fire of 1115 on Jiaozhou Road in Shanghai in 2010, the excellent fire protection characteristics of rock wool were paid attention to. Under the guidance of relevant policies, rock wool industry gradually entered the building insulation market, and the rock wool industry has been booming, and the production technology and equipment of rock wool have been greatly improved Step and development.

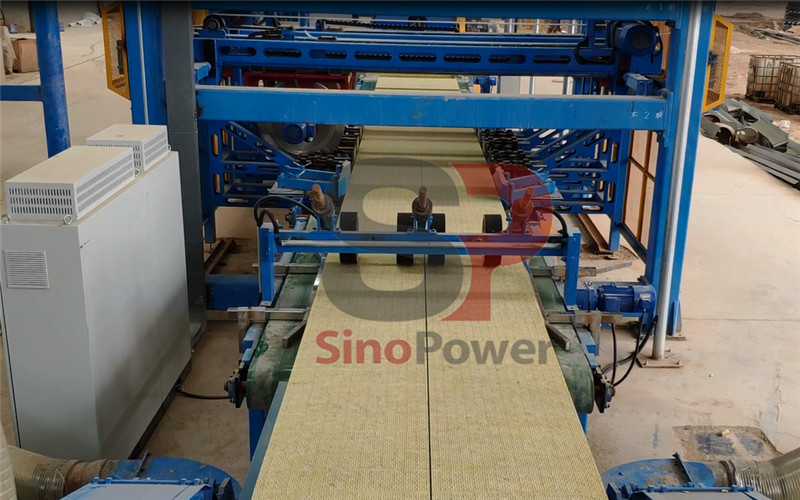

Sinopower Industries Group Limited can supply you high quality Insulation Rock Basalt Mineral Stone /Glass Wool Production Line Machinery. Welcome to visit our factory and working site.

Email:sinopowercn@gmail.com

Website:www.build-machine.com

Tiktok:Sinopower Group

WeChat Official Account:sinopowercn

Post time: Aug-14-2020