-

OPERATOR SKILLS Having examined differences in the equipment, next consider the operating challenges associated with these two systems. Hatschek: There are numerous opportunities to influence production results by changing the parameters for each agitator, sieve cylinder, fiber orientating screw,...Read more »

-

Now consider an overview of the differences between a Hatschek and Flow-on board machine with regard to slurry flows, starting with the preparation plant and ending with the finished green sheet at the forming roll. For both systems – Hatschek and Flow-on – the equipment following the forming rol...Read more »

-

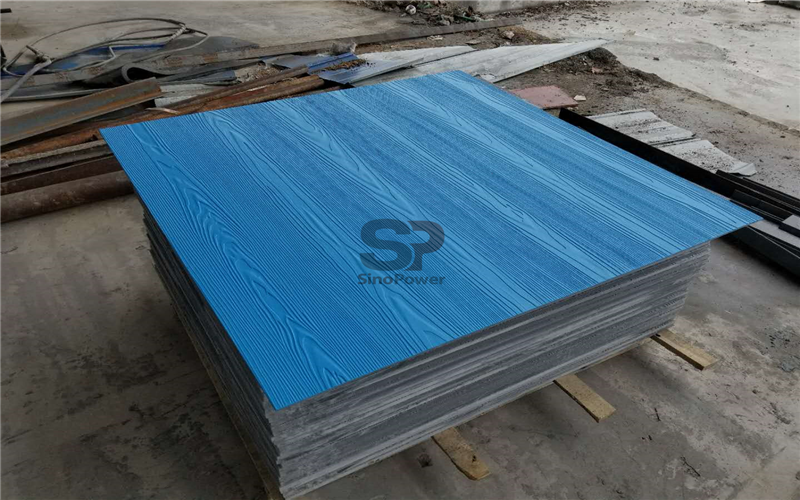

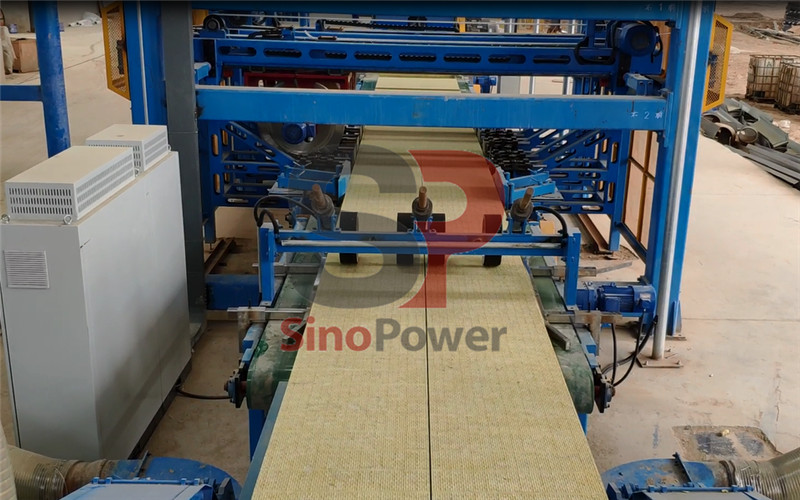

With the improvement of the global epidemic situation, the fiber cement board production line projects of sinopower and Gemini are moving forward smoothly and orderly. We have had many online meetings with the management and engineers of Gemini, and the local construction team is also carrying ou...Read more »

-

From December 17 to 18, the “2020 technical exchange conference of calcium silicate cement board industry” sponsored by the calcium silicate cement board branch of China concrete and cement products association was held in Binzhou, Shandong Province, a beautiful ecological city of the...Read more »

-

Fiber cement board Stone board Sound absorption and sound insulation performance The sound absorption effect is obvious after perforation compound treatment. Indoor marble will reflect sound, making the room reverberate for a long time. Thermal insulation performance...Read more »

-

At present, the single line production capacity of domestic mature mineral cotton products production line is 20000-30000 tons, but the existing technology can not meet the requirements of green production with larger capacity, lower energy consumption and more automation. In order to improve thi...Read more »

-

If rock wool production line wants to achieve the green production goal, it often needs to focus on the following points. One is to recycle carbon monoxide. Carbon monoxide is known to be toxic and has a greenhouse effect. But at the same time, carbon monoxide itself is a kind of fuel, which is t...Read more »

-

On August 31, 2020, Deyang basalt fiber industrialization development conference and the world’s first continuous basalt fiber product launch ceremony of 10000 ton tank kiln were successfully held in Deyang, Sichuan Province. This is an important grand event for Deyang Municipal government ...Read more »

-

1. Refining The refining of wood pulp fiber plays an important role in the bonding between the fiber and the substrate as well as the fiber reinforcement. However, the energy consumption of refining is high, which can be as high as 800 kwh / T. During the refining process, not only can the fiber ...Read more »

-

(Continued) Sustainability has been regarded as an important evaluation index for the long-term existence and sustainable development of industrial products in the world. Nowadays, the sustainability and green degree of products have become synonymous in a sense, because sustainable products must...Read more »

-

Sustainability has been regarded as an important evaluation index for the long-term existence and sustainable development of industrial products in the world. Nowadays, the sustainability and green degree of products have become synonymous in a sense, because sustainable products must be green. ...Read more »

-

Fiber cement board, also known as fiber reinforced cement board, is a kind of building cement board with fiber and cement as the main raw materials. With its superior performance, it is widely used in various fields of construction industry. The cement in the raw material of fiber cement board is...Read more »

-

The water-to-material ratio is not only to meet the needs of chemical reactions, but more importantly, to meet the needs of pouring and molding. It is a key process parameter that affects the formation of pores, pouring stability and product quality of autoclaved aerated concrete. Depending on th...Read more »

-

Technical principle: Through accurate, zoning and segmental control of the current and voltage of the slag furnace, the precise temperature control in the process of high temperature melt treatment can be effectively realized, and the homogenization of the melt can be promoted. The flow is contin...Read more »

-

High density fiber cement has a wide range of uses, almost suitable for designers for any building situation. The variety of textures and colors available enables it to be used in a variety of environments. Unlike metal parts, fiber cement building panels will not rust or corrode in any natural c...Read more »

-

According to the statistics of calcium silicate board / fiber cement board Work Department of China concrete and cement products association, in recent years, the annual growth rate of China’s calcium silicate board / fiber cement board is more than 30% (with the thickness of 6 mm. The annu...Read more »

-

The calcium to silicon ratio is the molar ratio of the total CaO to the total SiO2 in the constituent materials of autoclaved aerated concrete, written as C/S. The basic reason why aerated concrete can have high strength is that the calcareous materials and siliceous materials in aerated concrete...Read more »

-

1.Development status In foreign countries, rock wool thermal insulation material has been applied for decades, and it is one of the most mature materials in A-class fireproof materials. Rock wool insulation board is one of the inorganic thermal insulation materials. Compared with other A-class f...Read more »

-

Preface At present, organic thermal insulation materials are mainly used in most of the building exterior wall external insulation system, and the highest fireproof performance grade of these materials is B1. The design service life of the exterior wall external thermal insulation and enclosure s...Read more »

-

Autoclaved aerated concrete has excellent thermal insulation properties, and is the only wall material that can meet energy-saving requirements in a single material among wall materials. Autoclaved aerated concrete is used as a thermal insulation material for walls, which can fundamentally solve ...Read more »

-

In the construction stage of construction project, the construction unit needs to focus on how to reduce the climate conditions on the main structure of the building, and then extend its service life, which can effectively improve the problem of increasing energy consumption due to large indoor a...Read more »

-

(Continued) 2. Challenges Under the new economic normal, China’s economic structure will undergo fundamental changes. Adapting to the new normal means that industries and enterprises should be at a strategic position, recognize, adapt to, and even seek change, so as to meet the new challeng...Read more »

-

(Continued) II. Opportunities and challenges in the 13th five year plan 1. Opportunities 1.1 Market demand will remain high Although China’s economic development has entered a new normal, the market demand will remain high in terms of total volume. At present, China is in the key period of ...Read more »

-

“The 13th five year plan” is the decisive stage for China to build a moderately prosperous society in an all-round way. It is also a key period for China’s concrete and cement products industry to realize transformation and upgrading. Based on the summary of the development of c...Read more »

-

The autoclaved aerated concrete block produced by autoclaved aerated concrete production line is a new kind of green and environment-friendly self-insulation wall material, which is made of river sand, lime and cement as the main raw materials, aluminum paste as the foaming agent and foam stabili...Read more »

-

With the continuous improvement of building performance and safety requirements, new thermal insulation materials have become an indispensable part of buildings. We want to live in a house that not only saves energy, but also saves engineering costs. The board not only has the function of heat pr...Read more »

-

(Continued) 5.Comparison with international standards and foreign standards Fiber cement board has been developed for 60 years in foreign countries. The product variety is mainly asbestos cement board. The research shows that asbestos fiber dust has a harmful effect on human being exposed to this...Read more »

-

(Continued) 3.2 Calcium silicate board Calcium silicate board is a kind of building material which is made of siliceous material (main component SiO2, such as quartz powder, fly ash, diatomite, etc.), calcareous material (main component is Cao, such as lime, calcium carbide mud, cement, etc.), re...Read more »

-

1.Preface Fiber cement products are usually divided into fiber cement board, fiber cement pipe and fiber cement corrugated tile. Fiber cement board and calcium silicate board are common building decoration materials in the market, and they are also the two main flat products produced by fiber cem...Read more »

-

Compared with other rock wool products, the use of rock wool insulation board will be much larger, we usually think of the construction industry first. Because rock wool insulation board has very good performance, fire protection, heat insulation, thermal insulation, sound insulation, etc., which...Read more »

-

Melting system – high capacity furnace and preheating technology of oxygen enriched combustion and combustion supporting air The melting capacity of the furnace is 3.0 T / h. The furnace is equipped with oxygen rich, high temperature combustion supporting air system and waste gas treatment ...Read more »

-

With the acceleration of construction industrialization and residential industrialization, the domestic demand for fiber cement board / calcium silicate board is increasing day by day. At present, the fiber cement board / calcium silicate board produced in China has increased from 36 production l...Read more »

-

(Continued: Raw material ) Enhancer: the non steaming board produced by papermaking method or pulping method is of layered structure. In theory, the board with this structure is easy to be layered after freezing and thawing. So it is not suitable for outdoor use in cold areas. In fact, the freeze...Read more »

-

China environmental label product certification is aimed at the non asbestos fiber reinforced cement board industry. It shows that the product is not only qualified in quality, but also meets the specific environmental protection requirements in the process of production, use and disposal (it is ...Read more »

-

Fly ash is the ash particles collected after burning pulverized coal, also known as fly ash. Its chemical composition is mainly SiO2 (45-65%), Al2O3 (20-35%), Fe2O3 (5-10%) and CaO ( 5%) etc. After fly ash is mixed into concrete, it can not only replace part of the cement, reduce the cost of conc...Read more »

-

On May 21, New Element (Hubei) New Wall Materials Co., Ltd. officially launched trial production. In the comprehensive resumption of work and production, the trial production of New Elements projects is like a ray of spring, which makes people see the vitality of the new building materials indust...Read more »